A case erector machine takes collapsed boxes made of cardboard and builds them up into boxes that can be used again. They form these boxes by folding the cardboard. Once it is a full box again, they seal the bottom and top flaps with glue to secure and do not move around. This keeps the box safe and steady, as well as the contents inside. These case erectors are available in the market in many different sizes and forms to fit your need best for small scare businesses, large scale businesses, and niche businesses. Here are five things a case erector machine does.

Manual labor

These case erector machines eradicate the need for manual labor, as they automatically do their job. They fold, form, and seal the boxes themselves without much human interjection. By investing in one of these machines, you will be able to let go of some of your employees, employ them elsewhere in your business, or simply will not need to hire many employees.

This will benefit you in the long run, as your labor costs will be cut short, thus increasing your profits. In addition, if you pair your case erector machine with a case sealer, your boxes will emerge fully formed, and there will be no requirement for any labor to help out. It will all be completely automatic.

Saves money

An average day of working is 8 hours long. In this shift, an employee would be able to make 1260 boxes, on average. A case erector machine would make 2880 boxes, which an employee would need to work 16 hours a day to complete. If we take the example of an employee that gets paid $14 every hour, he/she would then need to be paid $224. However, the case erector that works for 8 hours a day with one employee would cost $112. Thus, you would be saving $112 while you produce 2880 boxes in exactly half of the time.

Saves time

These case erector machines work at very high speeds. They can fully form an entire box from just cardboard in 7 seconds. This means these machines are much faster than humans. This can save your business a lot of time and increase your production speed. Most of these case erector machines can form 6 to 20 cases per minute.

So an employee would be able to assemble, on average, three boxes every one minute. So taking an average again, on one 8 hour shift day, not including breaks that the employee will take, he/she should fold and make about 1260 boxes.

In contrast to this, on one 8 hour shift day, minus any breaks, a case erector machine would make 2880 boxes. This is true if the case erector is running at six cartons per minute. The fastest case erectors available in the market today can make about 9600 cartons.

Fitting in

Another benefit that case erector machines have to offer is that they can very easily be integrated into your packaging line. You can also pair it with a case sealer so that all the processes can be done at once, which will save you a lot of time. Time is money!

Decrease your wastage

Case erector machines barely ever make a mistake. They almost always make the perfect box, which cuts down the costs of buying extra material in case of wastage. There is virtually no human error, as there is almost no manual labor involved. This will help you save more by decreasing your cost. You can do a million things with this extra money, such as buy more material, buy more machines, and invest back into your business.

Being square

The case erector machine forms corners that are perfectly square. This helps to stack the cartons above, as it provides a strong base and stable support for the cartons. This way, they will not fall over. The stable square corners allow the weight to be distributed evenly across, as it provides a foundation as the base. This will help you stack your cartons, boxes, and pallets. It will decrease the risk of these tipping over during transportation or loading/unloading.

Types of case erectors

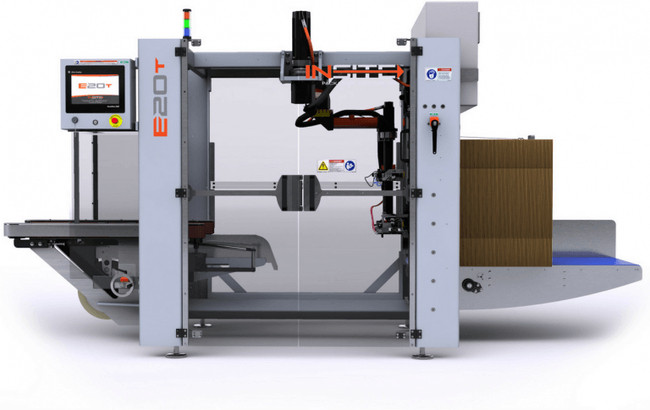

There are many different types of case erectors available in the market; all sizes, models, and styles, from different brands. Here, we will examine three of them.

Custom case erectors

This is the first type of case erector available in the market. This type of case erector allows you to program the machine to create the perfect custom box for you. This is perfect for businesses that are a niche or have custom box needs, such as a cake business. This custom case erector machine will fulfill all your unique packaging requirements.

Automatic case erectors

These automatic case erectors are perfect for a business that has a high supply and thus a high volume of boxes that need to be built. They are extremely high technology and very fast, along with super-efficient. They are great for quick changeovers too.

Semi-automatic erectors

Semi-automatic erectors are available in compact sizes and take up the most limited of spaces. These are great for when a business needs to save floor space and extra costs and is not a very large-scale operation. These erector machines are also great for when a business has a small or unusual area of space, as these machines come in all sizes, even the most awkward sizes. You can fit them anywhere!

Lastly!

It is very important that you choose the correct case erector, one that suits your business perfectly. This will help you optimize your output and profits, all the while decreasing your costs. It is a critical asset to have for a business that is in the packaging business.

Their new technology that applies hot glue to the package to seal it shut makes sure your package is secure and will not open. It also makes sure the content inside stays there and does not leak or spill out. Since case erector machines only make the best of the best, i.e., perfect boxes, your customers are guaranteed to be fully satisfied with the end result!