Draft beer has long been associated with freshness, superior taste, and a premium drinking experience. Whether you run a restaurant, bar, hotel, brewery taproom, or simply want professional-quality beer at home, a kegerator is the backbone of any reliable draft beer system. This in-depth guide explains what kegerators are, how they work, types of kegerators, key features to look for, installation and maintenance best practices, and how to choose the right kegerator for commercial or residential use. By the end, you’ll understand exactly what to look for before investing in one.

What Is a Kegerator?

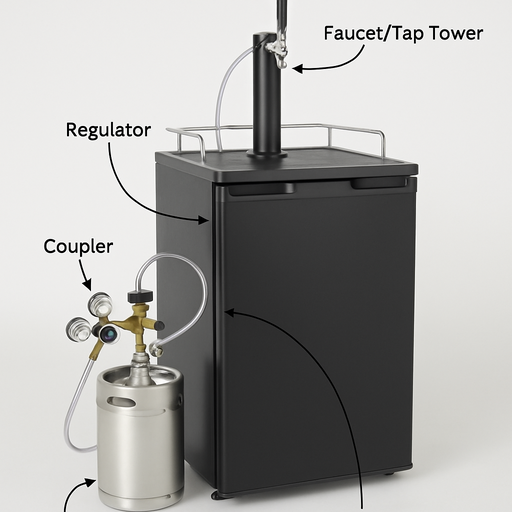

A kegerator is a refrigerated unit designed specifically to store, chill, and dispense beer from kegs. A kegerator is basically a mini-fridge and a beer tap rolled into one, designed specifically to keep a large keg cold and ready to serve. Unlike a standard refrigerator, a kegerator is equipped with draft beer components such as:

- Tap faucets

- Draft towers

- Keg couplers

- CO₂ or nitrogen tanks

- Pressure regulators

- Beer and gas lines

Together, these components allow beer to be served at optimal temperature and carbonation, producing a smooth pour with minimal foam and maximum flavor.

Kegerators are widely used in bars, restaurants, hotels, clubs, event venues, and breweries, as well as in high-end residential setups.

Meet the Team: The 5 Key Parts of Your Kegerator System

At its heart, a kegerator is a simple system where a team of components works together to deliver that perfect pint. Understanding these parts demystifies the whole process, turning what seems complex into something you can easily manage. The five key players are the CO2 tank, the regulator, the coupler, the beer line, and the faucet. The process starts with pressure. The CO2 tank is the engine of the operation, holding the food-grade carbon dioxide gas that both pushes the beer out and keeps it from going flat. But you can’t just connect a high-pressure tank directly to a keg. That’s where the regulator comes in. Think of it as the gas pedal; its gauges and dial let you control the exact amount of pressure (measured in PSI) going into the keg, which is the secret to avoiding a foamy mess.

Next in line is the coupler, which is the “key” that unlocks the beer. This device twists and locks onto the top of the keg, creating two ports: one for gas to go in and another for beer to come out. For nearly all commercial beers in North America—from big brands to local craft brews—you’ll use a Sankey D Coupler. Once connected, the CO2 pushes the beer out of the keg and into the beer line, the food-safe tube that acts as a highway to the tap. Finally, all that delicious beer travels up the beer line to the faucet and its tap handle. This is the gatekeeper, the final stop on the journey from the keg to your glass. When you pull the handle, the faucet opens, and a perfect, brewery-fresh beer is served. With this team working in harmony, you have everything you need for draft beer on demand.

Main Components of a Kegerator

Understanding the core components helps buyers evaluate quality and performance.

Refrigerated Cabinet

The cabinet keeps beer cold and stable. Commercial models typically feature stainless steel exteriors, heavy insulation, and high-capacity compressors.

Draft Tower and Faucets

The tower holds one or more faucets. Multi-tap towers allow different beers to be served from the same unit.

Keg Coupler

The coupler connects the keg to the beer and gas lines. Different beers and regions use different coupler types.

CO₂ Tank and Regulator

CO₂ provides pressure to dispense beer while maintaining carbonation. Regulators control PSI levels precisely.

Beer Lines and Gas Lines

Food-grade tubing carries beer and gas. Line length and diameter affect pour speed and foam control.

Drip Tray

Collects overflow and keeps service areas clean. Commercial kegerators often include built-in drain systems.

Types of Kegerators

1. Home Kegerators

Designed for personal use, these typically hold one keg and feature one or two taps. They’re compact, quieter, and easy to install.

2. Commercial Kegerators

Built for high-volume use, commercial units feature:

- Larger capacities

- Multiple taps

- Heavy-duty compressors

- Stainless steel construction

Brands such as Beverage-Air, True, Dukers, and Turbo Air are commonly used in professional foodservice environments.

3. Undercounter Kegerators

Perfect for bars and kitchens with limited space. These fit beneath countertops while delivering commercial performance.

4. Multi-Tap Beer Dispensers

Designed for busy venues, these units can support anywhere from 2 to 12 or more taps, allowing multiple beer styles to be served simultaneously.

5. Outdoor Kegerators

Built with weather-resistant materials for patios, rooftop bars, and outdoor venues.

Key Features to Look for When Buying a Kegerator

Capacity

Choose based on how many kegs and taps you need. Restaurants and bars typically require multi-keg capacity.

Tap Configuration

Single-tap units work for limited menus, while multi-tap systems are ideal for diverse beer selections.

Temperature Control

Precise digital thermostats allow consistent serving temperatures, usually between 34°F and 38°F.

Compressor Quality

A powerful compressor ensures rapid cooling and reliable operation during peak service hours.

Construction

Stainless steel interiors and exteriors improve durability, hygiene, and longevity.

Energy Efficiency

Commercial kegerators often include energy-efficient components to reduce operational costs.

Should I Get a Dual Tap Kegerator? (And Other Features to Look For)

As you start your search, you’ll quickly notice models with two taps instead of one. The biggest of the dual tap kegerator benefits is obvious: variety. You can have a light pilsner and a rich stout on tap at the same time, ready for any guest or mood. But since both kegs share one CO2 tank, how do you set the pressure? The solution is a simple compromise. You just find a happy medium—often around 12 PSI—that works well enough for both beers. For most people, it’s a small trade-off for having double the choice.

While the number of taps is a big decision, what controls the temperature inside is just as crucial for the best kegerator for home use. Look for units with a digital thermostat, which lets you set the temperature to an exact degree (usually 38°F or 3°C is perfect). This is a major upgrade over basic models with a simple “cold-to-coldest” dial, as it takes all the guesswork out of preventing foam and keeping your beer perfectly carbonated.

Finally, consider where you’ll place your kegerator and the materials it’s made from. If you dream of having fresh draft beer by the grill, you’ll need a dedicated outdoor kegerator. These are built with weatherproof components and more powerful cooling systems to handle the elements. A quick search for outdoor kegerator reviews will show you which models are up to the task. For any kegerator, indoor or out, stainless steel towers and faucets are also a worthy upgrade, as they are more durable and sanitary than chrome-plated parts.

How Long Does a Keg Really Last? Freshness, CO2, and Storage Explained

One of the best parts of owning a kegerator is having fresh beer on tap, but how long does that freshness actually last? The answer depends almost entirely on the type of beer you’re pouring. Most big-name domestic lagers are pasteurized, a heat-treatment process that extends their shelf life to a solid two to three months. The majority of craft beers, however, are unpasteurized to protect their more delicate and complex flavors. For these kegs, you’ll want to finish them within four to six weeks to enjoy them at their peak, before the flavor profile starts to change.

You might be wondering what stops the beer from going stale like an open bottle would. The secret is the CO2 in your system, which does much more than just push the beer to your faucet. It creates a protective, pressurized blanket over the surface of the beer inside the keg. This barrier prevents oxygen—the #1 enemy of beer freshness—from ever touching the liquid. It’s this constant protection from oxygen that stops your beer from developing a flat, cardboard-like taste, keeping it brewery-fresh from the first pour to the last.

Of course, your keg is only good as long as you have CO2 to serve it. To know when your tank is getting low, just look at the high-pressure gauge on your regulator. A crucial tip: this gauge will stay in the “full” zone for a long time and then drop very quickly as the last of the liquid CO2 turns to gas. Once you see that needle finally start to move down from its top position, it’s time to get a refill. A standard 5 lb tank typically lasts for 6-8 full-sized kegs, giving you plenty of notice.

Popular Commercial Kegerator Brands Available on HorecaStore (TheHorecaStore.com)

HorecaStore carries a wide range of professional beer dispensers from trusted manufacturers, including:

Beverage-Air single-tap and multi-tap kegerators

True multi-keg commercial beer dispensers

Dukers stainless steel kegerators with extended compressor warranties

Large-capacity draft beer systems for bars and event venues

These models are designed for durability, consistent performance, and high-volume service.

Final Thoughts

A kegerator is more than just a beer refrigerator—it’s a complete draft beer system that ensures freshness, consistency, and professional presentation. Choosing the right kegerator depends on capacity, usage volume, build quality, and maintenance requirements.

Whether you’re equipping a commercial bar or upgrading your beverage service, investing in a high-quality kegerator delivers long-term value, operational efficiency, and superior beer quality.