Introduction

Signal analysis lies at the heart of modern electronics, wireless communication, and research environments. Every device that processes, transmits, or interprets electrical signals relies on accurate measurement tools to understand how systems behave under real conditions. Engineers depend on clear waveform visibility to diagnose faults, confirm performance, and validate complex designs. Without proper visualisation and analysis, even the most advanced circuits can fail to operate as intended. The ability to see and interpret signal activity gives teams the insight needed to solve problems efficiently and maintain consistent operational standards.

As technology continues to advance, measurement demands grow more sophisticated. High speed devices, precision components, and complex integrated systems require instruments that offer clarity and reliability. Understanding how these tools work and what sets them apart helps engineers choose the most appropriate solutions for their workflows. From fundamental troubleshooting to advanced validation, signal analysis ensures that every stage of development supports accuracy, quality, and performance. A strong foundation in measurement tools not only improves outcomes but also helps organizations maintain efficient, predictable engineering processes.

The Role of Signal Analysis in Today’s Electronic Systems

Signal analysis plays a central role in understanding how electronic systems behave. Every circuit produces waveforms that reveal information about timing, stability, voltage levels, and overall functionality. By studying these characteristics, engineers can pinpoint irregularities that may lead to malfunction or reduced efficiency. Whether working on embedded systems, communication modules, or power electronics, teams rely on accurate waveform interpretation to verify that their designs function as intended.

In production environments, signal analysis supports quality control by confirming that each unit meets performance standards. Even minor variations can indicate potential issues that must be addressed before products reach users. Analysis also assists in predicting how devices respond to environmental changes, load variations, or electromagnetic interference. As systems become more compact and faster, understanding these details becomes essential for maintaining reliability. Signal analysis ensures that every stage of design and development is grounded in clear, actionable data.

Types of Instruments Used for Waveform and Frequency Measurement

A wide range of instruments support signal measurement across engineering and research fields. Each tool offers different strengths depending on the type of waveform, frequency range, or diagnostic goal. Many organizations explore combinations of digital solutions to achieve broad coverage in both troubleshooting and design validation. As measurement technology expands, teams have access to advanced tools that provide faster processing, greater accuracy, and improved visibility for complex systems.

To meet these needs, companies often rely on providers that support flexible sourcing models. Testwall reflects this demand. Founded in 2003, Testwall is a trusted provider of refurbished test and measurement equipment serving clients across manufacturing, telecommunications, defence, and aerospace. With offices across Europe including the UK, Ireland, Germany, France, and Poland, the company supplies high quality calibrated equipment, rental options, and repair services through its in- house laboratory. Its engineers offer tailored recommendations and guidance, ensuring organizations can access reliable tools that fit both technical requirements and budget considerations. These services help teams integrate essential measurement devices without compromising performance or operational efficiency.

Core Criteria for Choosing the Right Measurement Device

Selecting the right measurement device requires a precise understanding of both the electrical signals being analyzed and the demands of the testing environment. Engineers need tools that can capture, process and display waveform data accurately without introducing errors that could influence results. By examining core performance characteristics, teams can determine whether a device aligns with their workflow and supports the level of detail required for meaningful analysis. The following criteria outline the key aspects that guide this selection process and help ensure that the chosen instrument delivers dependable performance.

- Bandwidth and sample rate: Bandwidth and sample rate determine how effectively a measurement device can capture fast, complex or high frequency signals. Engineers assess whether the instrument can preserve signal integrity without distortion or loss of detail. Higher bandwidth supports accurate reproduction of rapid transitions, while an appropriate sample rate ensures enough data points are collected to represent the waveform correctly. Matching these specifications to the signals being tested is essential for reliable analysis.

- Channel count: Different projects require different levels of visibility across multiple signals. Channel count influences how many inputs can be monitored at once and how easily teams can compare interactions between system components. Engineers consider whether they need two, four or more channels to support their testing environment. Choosing the right channel configuration prevents bottlenecks during analysis and ensures that all relevant signals can be captured simultaneously.

- Triggering options: Triggering functions help stabilize a waveform on the display and allow users to isolate specific behaviors or events. Advanced triggering options can identify patterns, glitches or anomalies within complex signals. Engineers review which trigger modes a device offers and how effectively these modes support the type of testing being performed. Strong triggering capabilities make it easier to diagnose issues and capture rare or intermittent events with precision.

- Memory depth: Memory depth affects how much waveform data can be stored during a single acquisition. Larger memory enables the device to record longer time windows at higher sample rates without sacrificing resolution. This is especially important for applications that involve extended observations or detailed analysis of signal sequences. Teams evaluate memory depth to ensure the device can handle their expected data volume without forcing compromises.

- Portable versus benchtop design: Form factor plays a role in workflow efficiency. Portable models support field work, maintenance tasks and locations where mobility is essential. Benchtop designs often provide greater performance, larger displays and expanded feature sets for laboratory environments. Engineers consider whether the convenience of portability outweighs the capabilities of a stationary unit or vice versa. The right choice depends on where and how the device will be used.

Evaluating these criteria gives engineers a structured foundation for selecting a device that aligns with their technical goals and project conditions. Each factor plays a role in how effectively the instrument can capture, store and interpret waveform information. By weighing these elements carefully, teams can avoid capability gaps, streamline their testing procedures and maintain high confidence in the data they collect. Strong decision making at this stage leads to smoother diagnostics, more accurate measurements and long term reliability across a wide range of applications.

How Signal Visualization Enhances Troubleshooting and Validation

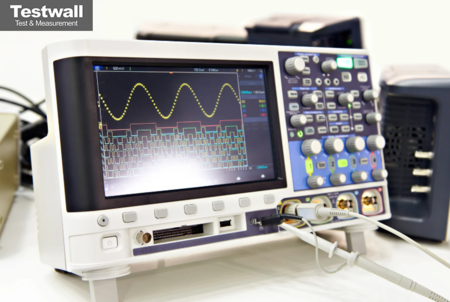

Signal visualization offers engineers a detailed understanding of how circuits behave in real time. When waveforms appear on the screen, technicians can observe voltage changes, signal distortions, and timing irregularities that may not be visible through basic testing methods. This clarity speeds up troubleshooting by helping teams identify the root cause of issues quickly. Signal visualization is especially important in high speed systems, where unexpected spikes or drops can affect the stability of an entire network or device.

During design validation, engineers rely on visual tools to confirm that systems operate within expected specifications. For example, waveform analysis can reveal whether a signal transitions smoothly, whether digital pulses remain stable, or whether noise is affecting performance. These insights allow teams to make targeted adjustments that improve reliability and efficiency. By incorporating visual measurement methods into the workflow, organizations maintain accuracy across development cycles and reduce the risk of defects or operational failures.

Common Mistakes When Interpreting Waveforms and How to Avoid Them

Interpreting waveforms requires attention to detail and a thorough understanding of measurement principles. Even experienced engineers can encounter errors when devices are configured incorrectly or when environmental factors affect readings. These mistakes may lead to inaccurate conclusions, missed faults, or unnecessary troubleshooting steps. To avoid these issues, teams review common problem areas and apply best practices during each measurement session. Frequent mistakes include:

- Incorrect probe selection: Selecting the wrong probe can dramatically affect the accuracy of a waveform measurement. Each probe is designed for a specific voltage range, frequency response, and application type. Using a probe that cannot handle the signal’s characteristics may cause distortion, attenuation or even equipment damage. Engineers evaluate probe ratings carefully to ensure the accessory matches the signal conditions and preserves measurement integrity.

- Misconfigured triggering: Improper triggering settings often lead to unstable or inconsistent waveform displays. If the trigger level, mode or source is not configured correctly, the oscilloscope may fail to lock onto the event of interest. This can make waveforms appear jittery or unpredictable. Reviewing trigger settings before each measurement helps stabilize the display and ensures critical events are captured with clarity.

- Overlooking noise and distortion: External interference, poor shielding and nearby electronic devices can introduce noise that masks important signal details. Failing to recognize or filter out this distortion may result in false assumptions about circuit behavior. Engineers monitor the testing environment, apply appropriate filtering and verify signal quality to prevent noise from influencing their conclusions.

- Misreading peak and RMS values: Incorrect interpretation of amplitude values can lead to faulty analysis, especially when comparing real time signals to design specifications. Peak values represent the highest instantaneous voltage, while RMS values indicate the signal’s effective power. Confusing these measurements may cause engineers to misjudge load conditions or performance limits. Understanding when to apply each measurement ensures more accurate evaluations.

- Neglecting grounding practices: Poor grounding can introduce unwanted artifacts, create safety risks and distort waveform readings. Floating grounds, improper reference points or inadequate shielding may alter the true signal signature. Engineers ensure proper grounding connections, use differential probes when necessary and follow recommended safety procedures to maintain clean, reliable measurements.

Awareness of these pitfalls helps engineers maintain accuracy throughout the testing process. By reviewing configuration settings, selecting the correct accessories, and maintaining proper grounding, teams reduce the likelihood of misinterpretation. Training and consistent workflow practices also contribute to improved analysis. A structured approach ensures that each waveform is evaluated reliably, leading to faster issue resolution and stronger overall system performance.

Comparing Modern Digital Tools with Other Diagnostic Methods

Digital measurement instruments have transformed how engineers analyze waveforms and frequencies. Their processing speed, storage capacity, and advanced triggering capabilities provide insight that older tools cannot match. High resolution displays, fast update rates, and automated measurement features streamline the diagnostic process and reduce the time required to identify faults. These advantages make digital platforms valuable across industries that require precision and rapid troubleshooting.

Organizations seeking these capabilities often look for flexible, cost effective sourcing options. Testwall demonstrates how well maintained refurbished equipment supports modern engineering needs. The company offers fully tested and calibrated instruments that meet original manufacturer specifications through its in- house calibration laboratory. Its rental services, repair solutions, and buyback program give teams multiple ways to access high quality equipment without overspending. Backed by ISO 9001:2015 certification and experienced engineers who provide expert advice, Testwall supports businesses with reliable tools, fast tracked delivery, and warranty backed assurance. These services ensure that digital measurement technologies remain accessible for organizations of all sizes.

Real-World Applications Across Engineering, Manufacturing, and Research

Waveform analysis plays a valuable role in many technical fields. In electronics manufacturing, it supports quality control by verifying signal stability and ensuring that each product matches design specifications. Production teams rely on waveform measurements to validate circuits, detect irregularities, and confirm performance before items move to final assembly. This process helps reduce defects and maintain consistent standards across large batches of components.

In telecommunications, signal analysis is essential for maintaining network stability. Engineers monitor waveform behavior to ensure that data transmission meets timing, clarity, and strength requirements. As communication systems become more complex, waveform monitoring helps identify issues related to bandwidth, interference, or system overload. Research institutions use waveform tools to analyze experimental signals and evaluate prototype designs, supporting innovation across multiple scientific fields. By applying waveform analysis to real world scenarios, teams can maintain reliability and progress in demanding technical environments.

Final Section: Choosing Tools That Support Accurate, Future-Ready Signal Analysis

Building a measurement strategy that supports long term performance requires thoughtful planning and the right selection of tools. Engineers who understand their system requirements can choose instruments that align with both current needs and future development goals. Providers such as Testwall offer solutions that help organizations access these technologies efficiently. Testwall reflects this commitment by offering refurbished test and measurement equipment, rental options, calibration services, and a buyback program that simplifies equipment transitions. Its ISO certified processes, warranty backed support, and expert guidance give teams confidence when integrating new instruments into their workflows.

As industries evolve, accurate signal analysis remains central to innovation and quality assurance. Organizations that invest in reliable instruments and structured measurement practices strengthen their technical capabilities and reduce the risk of system failures. By combining high performance tools with flexible acquisition models, teams create testing environments that are resilient, adaptable, and ready for future demands. Signal analysis will continue to shape the reliability and efficiency of modern technology, making these tools essential for every engineering discipline.